CLIENT: KAILAS

TECHNIQUE: For this project we delved into pursuing first-class materials that could ensure maximum comfort in extreme conditions, especially regarding the 8000+ series. These features include hyper-insulating and water-tight properties, accompanied by cutting edge graphic design.

COLLABORATION: Our founder Fabio Deon has been developing several products for Kailas, working as head designer and art director for the shoe division. Some models in display represent the 8000+ series aimed at serving hyper-performing athletes , inspired from the Himalayas.

CLIENT: DEMON

TECHNIQUE: This project aims at cross-pollinating elements that come from both the fashion environment and the hyper-performative know-how of the Studio. Chrome-free, enviromental-friendly treatment of precious Tuscan and Venetian leathers is juxtaposed with forward-looking graphical choices and hard core original Vibram soles.

COLLABORATION: Demon is an ancillary project born in sinu of Studio Deon.

CLIENT: AMUNDSEN

TECHNIQUE: This project implied the usage of the most recent technical solutions , molded to the identity of the historic brand and family of Amundsen. One of the most iconic features is the gaiter, developed in several materials and coloring.

COLLABORATION: The collaboration started from Fabio’s fascination for the brand and its unique history. Fabio and Jorgen, currently heading the company, agreed to expand the brand ‘s production arrays by entering the shoe market with the boots eventually baptized as the Mountain Muck.

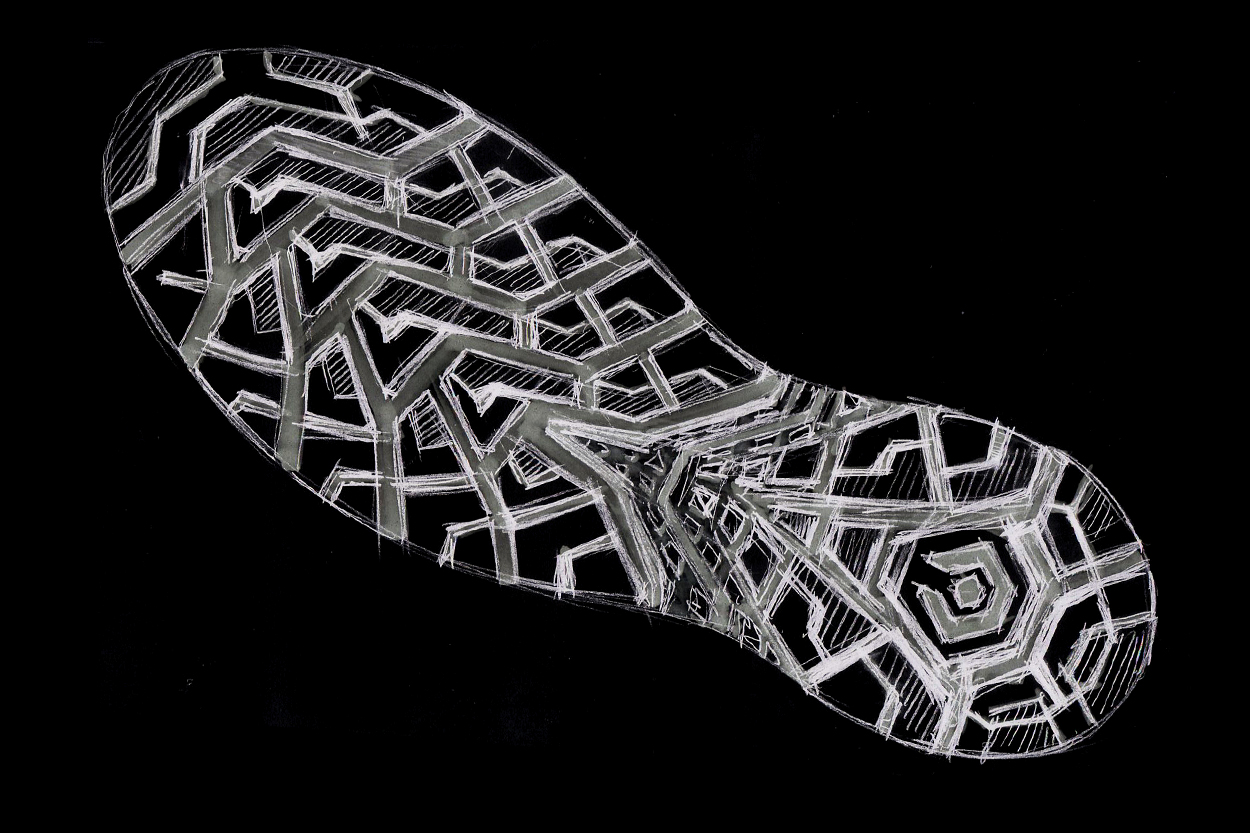

CLIENT: BETA

TECHNIQUE: In this project, the most salient technique utilized are injections: this safety shoe consists of a sock embraced by an outer shell on which graphics are applied. The goal of the project was to realize the lightest shoe on the market.

COLLABORATION: Between Beta and Studio Deon elapses a collaboration that started from the design of the product and matured into the relaying on the Studio for development. While initial design was conceived in Italy, this last phase was handled in China, exploiting the Studio’s facilities and network.

CLIENT: SPIDI for ALYX

TECHNIQUE: The main task consisted in applying Alyx’s color palette on to Spidi’s motorbike boot.

COLLABORATION: This project was centered on the collaboration between Spidi and Alyx: the goal was reinterpreting Spidi’s technical shoewear with Alyx aesthetics. In this case, Studio Deon guided Spidi also through the phases of development and production.

CLIENT: BASE PROTECTION

TECHNIQUE: For Base’s project, the research revolved around an innovative assembling process, accompanied as well by outsole technology innovation. All held together by BOA closure system.

COLLABORATION: This collaboration evolved from the initial design concept up to the sourcing of the upper with its components.

CLIENT: ITURRI

TECHNIQUE: Since the hard-core usage, these boots had to undergo severe tests. All materials and design solutions needed to level up to these standards.

COLLABORATION: The work with Iturri revolves around the creation of several combat models, destined at international army corpses.

© STUDIO DEON DESIGN - ITALY - USA - CHINA.

P. IVA 03232580260

︎

P. IVA 03232580260

︎